Dramatically Cut

Workload and Cost of Maintenance

- Amazingly low loss of head achieved with a specialized valve body structure. Patented.

- Easy on-the-ground maintenance, even in the case of water drainage, making time?-consuming, pipe-lifting work unnecessary.

It is economical since it only requires the replacement of separately-sold maintenance parts. - Made of stainless steel and has a long life and highly durable design.

Do you have any trouble

with General Foot Valve?

-

Because the pump is submerged, it gets stuck and causes water to drain out!

Being submerged, the body of the pump rusts and becomes fixed, therefore resulting in the water draining out.

-

It’s impossible to raise!

Since the ceiling of the pump room is low, it’s hard to raise the valve and put it back in place.

-

Maintenance is time-consuming!

Maintenance requires several people and an entire day of work. It’s hard to work in the cold for long hours.

-

To prevent water draining,

the pump is operated 24-hours a day!

We are running the pump 24/7 to avoid water drainage but we know that this is a waste of electricity.

The cause of these problems is

a check valve

attached to the bottom of a suction pipe

in the water.

The Best solution is

Ground Foot Valve SG.

Patented.

The only Foot Valve

on the ground.

Three Realizations

with

Ground Foot Valve SG.

-

A Newly Developed Specialized Valve Body Structure

that Achieves Low Loss of Head, Far Surpassing the Foot Valve.- Since the resistance equivalent is equal to or less than that of the foot valve, it is possible to install SG on all the sites where foot valves are installed.

- Because it is a low resistance valve, the SG maximizes pump performance.

-

On-the-Ground Easy Maintenance Now in Your Hands

- Maintenance of the valve body, just by detaching the clamp, greatly improves work efficiency.

- Maintenance can be performed with ease.

- Urgent repair work after drainage is possible within in a short time and with only a small number of personnel, ensuring high productivity.

-

Stainless Steel Body Makes the Valve Adaptive to a Variety of Fields.

- The angle type design makes for easy maintenance.

- Due to durable stainless steel construction, replacement of the separately-sold maintenance parts makes long service life of the SG a reality.

Achievement

Achievement prove

reliability and durability of the product.

Many companies have decided to use

Ground Foot Valve SG

because they accepted the innovation and our service quality.

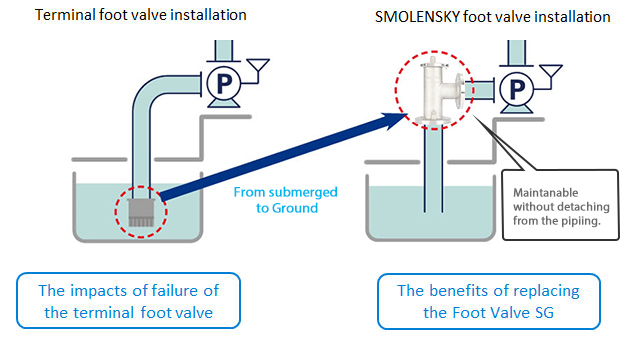

Change

From Submerged To Ground

The Solution to Failure to the Terminal Foot Valve

- In the case of draining, the piping needs to be raised and replaced.

- Suction failure causes dry running of the pump, resulting in failure.

- Any failure requires interruption of the production line, affecting the production.

- Since it is waterproofed with spring and gasket, it has high cut-off performance, and even though it is ground-based, it will not drain.

- Even in the case of draining due to jamming of foreign matter, it can be maintained on the ground, which saves time and labor.

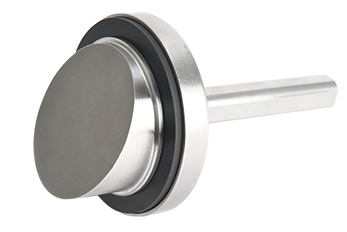

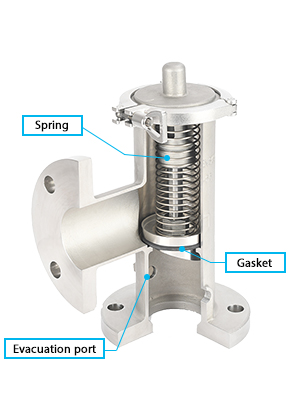

Why Doesn’t It Leak?

It is because of its double sealing force of spring and gasket.

It will not leak as it is sealed with spring and gasket.

Smolensky uses a lift type with high durability and a high-water cut-off.

If you want to remove the air on the primary side of the valve, you can also pump it with a vacuum pump from the pressure reduction port (3 / 8Rc).

※ It may leak due to the entry of dirt and other foreign objects. In that case, please carry out maintenance from time to time to restore the water stopper surface.

Because it is installed on the ground, maintenance can be done easily.

Maintenance of the terminal foot valve requires time and labor such as lifting and draining the water in the tank, but since this is installed on the ground, it can be easily removed.

Angle type valves can be maintained without removing them from the piping.

Many Clients have already used

the Ground Foot Valve SG.

Supplier: Metal/Non-ferrous Metal Industry

Piping type: Cooling

We profited by nearly 4,000,000 Yen

Even though we initially lost a profit of nearly 4 million yen, we bought it because of its ease of maintenance. In nearly two years, we have had no water drainage. Until we went with Smolensky, everything was done manually due to the concern of water dainage. However, now we are running everything by automatic operation. In addition to this, we stopped running the system on Saturdays and Sundays, so we converted the water fee and the electricity bill, and got nearly 4 million yen in profit. I am very satisfied that we were able to regain our investment so soon.

Supplier: Automobile Factory

Piping type: Cooling Water

The Cost is Zero Yen

From the point of installing the SG, the trouble of "I cannot drive the pump," is gone. I think there is no other product that meets the needs of facility managers as the SG does. With the original foot valves we were using, on the first day of every New Year, we were constantly working on restoring them. New Years in Japan is a time to relax and I always felt anxious, thinking "We are working on this again", but since we installed the SG, everything is very smooth and our anxiety has been eliminated. The cost is also 0/zero yen when you can do the maintenance yourself.

Supplier: Tenant Building

Piping type: Water Supply

Seven Units Already Installed

One year has already passed since we installed the Ground Foot Valve SG. At the time of using the conventional foot valve, it was necessary to work on it at least once a month, but since we changed to the SG there has been no drainage due to the entry of dirt or malfunction this year, and the pump constantly supplies water. Even if work is needed, I feel at ease because I know that it can be done without much effort because it is installed on the ground. Since installing the first unit, we were happy with the results so now we have already installed as many as seven units. In the future, we are planning to have internal parts for replacement as spare parts and we plan to be thoroughly prepared.

Supplier: Commercial Building

Piping type: Cooling

We Want to Use it for a Long Time

After installing the Ground Foot Valve SG, we have been using it without any troubles such as drainage or leakage. It is also nice to know immediately whether the SG is working, and this is done by simply attaching a vacuum gauge to the suction side. Even when there is trouble, it can easily be maintained on the ground. I am very satisfied. I would like to use it for a long time and plan to do so by replacing the internal parts when necessary.

Answer Your Questions

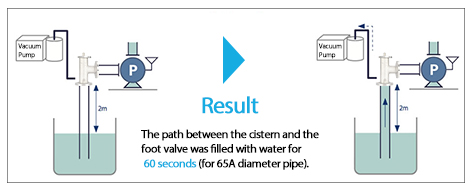

Q1. It seems impossible to prime the portion below the valve. How can this be?

Although there is a layer of air in the piping below the valve, by repeating the ON-OFF operation and by priming the pump, the water will pass through the system.

1) After foot valve installation

Install the foot valve. The piping, between the water level and the pump, is filled entirely with air. ※1

2) Prime the pump.

Prime the pump by filling the suction piping between the pump and the foot valve with water. ※2

3) Turn the pump ON and then OFF.

Turn on the pump and then turn it off 1-2 seconds later. This will pull up the water. ※3

Even after the pump stops, the water remains high. There is a layer of air remaining in the piping. ※4

4) Prime the pump again to fill the piping between the pump and the foot valve with water.

Prime the pump to fill the suction piping between the pump and the foot valve with water. ※5

When the pump is powered ON again and then powered OFF, the water is sucked up even more.

Repeat procedures 3) and 4) several times to allow the water to pass through the piping.

Q2. Is it true that drainage will not occur once the water is sucked up?

Using foot valve verification test equipment,

we observed the state of the water once it was sucked up.

The Result of our Demonstration Test

The valve was found to hold the water that was drawn for 180 days, without causing any drainage, and then when the pump was restarted, the water flow smoothly resumed.

Just like an experiment with a drinking straw, the valve is stopped with a spring, so no air gets in, and drainage does not occur.

*Be sure to avoid exposure of the end of piping above the liquid surface.

By installing a vacuum gage at the evacuation port, you can visually monitor, on the ground, the condition inside the piping below the valve.

Q3. Can I use it with an inverter pump?

Yes, you can.

By switching inverter control to commercial operation, you can prime your pump and allow water to pass according to the procedures in FAQ 1 above.

If you cannot isolate the inverter control, the priming will be easy by connecting a vacuum pump to the evacuation port.